Table of Contents >> Show >> Hide

When it comes to managing cooling systems in electronic devices, precise fan control is essential for optimizing performance and energy efficiency. One of the most common methods used to control fan speeds is Pulse Width Modulation (PWM). However, PWM, while effective, isn’t always ideal for scenarios that require more stable and consistent power delivery. This is where converting PWM to DC signaling can come into play. This process allows for more accurate and smoother control over fan operations, enhancing the overall experience in applications like PC cooling, server farms, and industrial systems. In this article, we’ll dive into the mechanics of PWM, the reasons why you might want to convert it to DC, and the benefits that come with this transformation for more precise fan control.

What is PWM and Why Is It Used for Fan Control?

Pulse Width Modulation (PWM) is a technique used to control the amount of power delivered to electrical devices, such as fans, motors, and LEDs. By rapidly switching the power on and off, the average voltage delivered to the fan is varied, which effectively controls its speed. The ratio of the on-time to the off-time is referred to as the duty cycle, and by adjusting this cycle, you can increase or decrease the fan speed.

PWM offers several advantages, such as simplicity, cost-effectiveness, and minimal heat generation compared to other methods like linear voltage regulation. However, the nature of PWM means that the fan receives pulses of energy, which can cause noise and vibrations, especially at low speeds. This is where converting PWM to DC becomes beneficial, as DC power provides a smoother and more stable current.

Why Convert PWM to DC Signaling?

Although PWM is a highly efficient method of fan speed control, there are situations where the pulse-driven nature of PWM is less than ideal. Here are a few reasons why you might want to convert PWM to DC signaling:

- Smoother Operation: PWM can cause the fan to experience periodic vibrations as it switches on and off. By converting to DC, the fan receives a constant voltage, leading to smoother, quieter operation.

- More Precise Control: DC signaling allows for finer control over the fan speed, particularly at lower duty cycles where PWM can become erratic. A steady DC voltage enables the fan to respond more predictably to changes in control signals.

- Reduced Noise: Fans operating on PWM signals can generate audible noise due to the rapid switching. By converting the PWM to a DC signal, the electrical noise is eliminated, making the fan operate more quietly, which is particularly desirable in sensitive environments such as audio equipment or office settings.

- Compatibility with Older Systems: Some older systems or more sensitive components may not be compatible with PWM control. Converting PWM to DC can ensure that the fan operates as intended without causing compatibility issues.

How to Convert PWM to DC for Fan Control

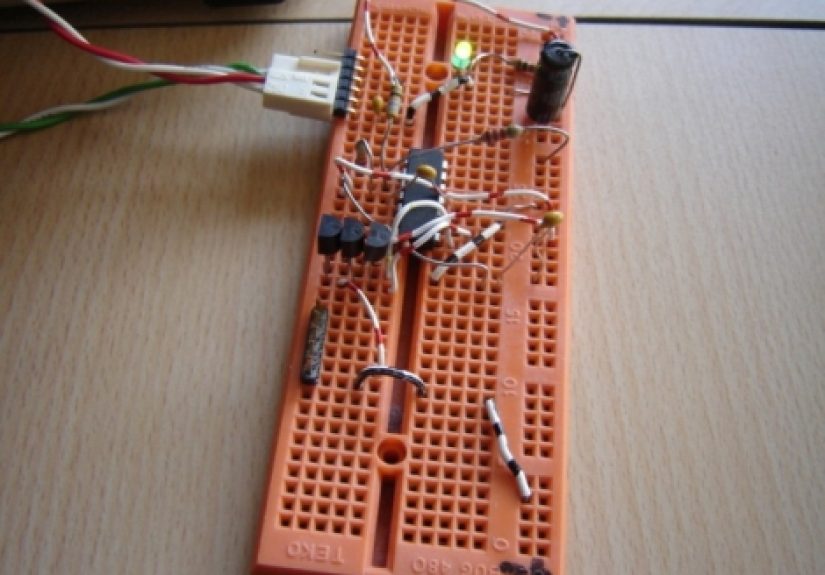

Converting PWM to DC isn’t as complicated as it may sound. The process typically involves using a low-pass filter to smooth out the pulses and deliver a steady DC signal to the fan. Here’s a basic overview of how this is done:

1. Low-Pass Filter

The most common method for converting PWM to DC is through the use of a low-pass filter. A low-pass filter works by allowing low-frequency signals (like the average DC voltage) to pass through while filtering out high-frequency components (the pulses from PWM). A simple RC (resistor-capacitor) circuit is often used for this purpose. The resistor limits the current, and the capacitor smooths out the variations in voltage, effectively turning the pulsed waveform into a more stable DC voltage.

2. Choosing the Right Capacitor

The value of the capacitor is critical in achieving the desired filtering effect. A larger capacitor can store more charge, which helps to smooth out the fluctuations in voltage. However, too large of a capacitor can result in sluggish responses to changes in fan speed. On the other hand, a smaller capacitor may not effectively filter the PWM signal. The optimal value will depend on the frequency of the PWM signal and the required smoothness of the output.

3. Adding a Voltage Regulator

In some cases, you may want to add a voltage regulator after the low-pass filter. This ensures that the DC voltage is stable and within the proper range for the fan. Voltage regulators can help maintain a constant output, even if the input voltage fluctuates. This is especially important for fans that are sensitive to voltage changes.

4. Fine-Tuning the System

Once the filter and regulator are in place, the system may need fine-tuning to ensure optimal performance. This involves adjusting the filter’s capacitor value or the PWM frequency to achieve the best balance between fan speed stability and responsiveness. Testing the setup in real-world conditions will help identify any adjustments that need to be made.

Benefits of Converting PWM to DC

The process of converting PWM to DC signaling provides numerous benefits for fan control in various applications:

1. Improved Fan Longevity

By providing a smoother and more stable power supply, DC signaling reduces the mechanical strain on the fan motor, which can lead to a longer lifespan. PWM, on the other hand, may cause the fan motor to experience more wear and tear due to the constant switching on and off.

2. Better Power Efficiency

When a fan operates on a steady DC voltage, it can achieve better efficiency in power consumption. PWM, while efficient in controlling speed, can cause fluctuations in power delivery, leading to less efficient energy usage in some cases. DC voltage provides a more consistent energy supply, which can contribute to overall energy savings.

3. Quieter Operation

Fans powered by PWM can often produce an audible whine or hum, particularly at lower speeds. Converting to DC eliminates this noise, making the fan quieter and more suitable for noise-sensitive environments like home theaters, audio studios, or office spaces.

Practical Applications of PWM to DC Conversion

The ability to convert PWM to DC signaling for more precise fan control has wide-reaching implications across various fields:

- PC Cooling Systems: In personal computers, particularly high-performance gaming PCs and workstations, cooling systems need to operate quietly while still being effective. Converting PWM signals to DC can help achieve the optimal balance between noise and cooling performance.

- Server Farms: Large-scale server farms rely heavily on efficient cooling. With precise fan control, operators can ensure that fans are running optimally, reducing noise and energy consumption while maintaining proper temperatures.

- HVAC Systems: In HVAC systems, fan speed control is crucial for maintaining air quality and comfort. Converting PWM to DC allows for more precise control over fan speeds, ensuring that the system operates efficiently without generating unnecessary noise.

- Audio Equipment: High-end audio equipment often requires fans to cool sensitive components. Using DC-controlled fans ensures that the system remains quiet, which is essential for audio clarity and performance.

Challenges and Considerations

While converting PWM to DC for fan control offers numerous benefits, there are also a few challenges to consider. For instance, implementing the necessary componentssuch as low-pass filters, capacitors, and voltage regulatorsadds complexity to the circuit design. Additionally, fine-tuning the system to ensure optimal performance can require careful adjustment. However, with the right approach, these challenges can be overcome, and the benefits of smoother, quieter, and more precise fan control are well worth the effort.

Conclusion

Converting PWM to DC signaling for more precise fan control can significantly improve the performance, efficiency, and longevity of cooling systems. By utilizing low-pass filters and voltage regulators, users can eliminate the noise and vibrations associated with PWM-driven fans while enjoying smoother operation and more accurate speed control. Whether for PCs, server farms, HVAC systems, or audio equipment, this conversion method provides a clear advantage in terms of both user experience and system efficiency.

Experiences with Converting PWM to DC for Fan Control

Throughout various projects and installations, the conversion of PWM to DC has proven to be an effective way to enhance the precision and reliability of fan control. In one particular case, a DIY PC enthusiast converted the PWM-controlled fan system in their custom-built gaming rig to DC. The result? A noticeable reduction in noise and a smoother cooling experience, particularly at lower fan speeds.

For those in industrial or server environments, the benefits of converting PWM to DC are especially evident in larger cooling systems. One case involved a server farm where the team implemented DC-controlled fans in place of PWM-driven ones. Not only did this change improve the noise levels in the facility, but it also led to more consistent fan speeds, reducing the likelihood of overheating or unnecessary power consumption.

On the flip side, there are some practical challenges in making this conversion work. The need to carefully select capacitors and fine-tune voltage regulators can be a trial-and-error process. Some users have found that the initial setup was more complex than they anticipated. However, once the conversion was completed successfully, they reported increased fan longevity and better overall system stability.

Overall, converting PWM to DC is an excellent way to optimize fan control in a variety of settings, offering quieter, more efficient operation. Whether you’re a hobbyist building your own computer or managing large-scale industrial systems, this conversion method can provide long-term benefits in performance and energy savings.