Table of Contents >> Show >> Hide

- Plan First: Size, Seating, and Style (So You Don’t Build a “Regret Table”)

- Tools and Materials (Minimal, Practical, and Not a “Garage Full of Chaos”)

- A Simple, Sturdy Build Plan: 6-Foot Rectangular Kitchen Table

- Step-by-Step: Build Your Kitchen Table

- Step 1: Prep the wood (the boring step that makes everything easier)

- Step 2: Build the base frame (legs + aprons)

- Step 3: Add corner bracing and a stretcher (sturdiness upgrade)

- Step 4: Build the tabletop (the “big glue-up” moment)

- Step 5: Flatten, sand, and soften edges

- Step 6: Attach the top the right way (wood movement matters)

- Step 7: Finish for real kitchen life (heat, spills, and chaos)

- Step 8: Stop wobble before it starts

- Common Mistakes (So You Don’t Have to Learn Them the Hard Way)

- Easy Upgrades That Make Your Table Look Custom

- Real-World Experiences: What Building a Kitchen Table Actually Feels Like ()

- Final Thoughts

A kitchen table is basically a piece of furniture that moonlights as a homework desk, a coffee bar, a

“why is there glitter here?” craft station, and the meeting room for every family decision from

“what’s for dinner?” to “who ate the last cookie?” Building one yourself means you get the size you

actually need, the style you actually like, and the sturdiness your future self will thank you for

(especially when someone inevitably leans back in their chair like they’re auditioning for a slapstick

comedy).

This guide walks you through planning, materials, a beginner-friendly build process, and the small

details that separate “I built a table!” from “I built a table that doesn’t wobble when someone

breathes near it.” We’ll also cover the sneaky woodworking concept that ruins more tabletops than

spilled spaghetti: wood movement.

Plan First: Size, Seating, and Style (So You Don’t Build a “Regret Table”)

Pick a size that fits real life

Start with two measurements: the space you have and the number of people you want to seat. Many

comfortable kitchen and dining tables land around 29–30 inches tall. For seating,

plan roughly 24–30 inches of table edge per person so elbows aren’t constantly

negotiating borders like tiny diplomats.

Quick examples:

- Small kitchen: 48″ × 30″ seats 4 comfortably and doesn’t eat the room.

- Typical family table: 60″–72″ × 36″ is a great everyday sweet spot.

- Narrow space: Consider 30″ wide with a bench on one side to save clearance.

Choose a style that matches your skill level

If you’re new to woodworking, pick a design that’s structurally strong without requiring fancy joinery.

A classic “farmhouse” look (straight legs, aprons, thick top) is popular because it’s forgiving and

sturdy. Prefer modern? A simple rectangular top with premade legs can look high-end with less build

complexity.

Tools and Materials (Minimal, Practical, and Not a “Garage Full of Chaos”)

Beginner-friendly tool list

You can build a solid kitchen table with a modest setup. The safest path (especially for teens) is to

have an experienced adult help with any cutting toolsor have lumber cut at the store.

- Measuring tape, pencil, speed square

- Drill/driver + bits

- Clamps (more than you think you need… and then one more)

- Sander or sanding block + sandpaper (80/120/180/220 grit)

- Pocket hole jig (optional but helpful for clean assembly)

- Wood glue, screws (including pocket screws if using a jig)

- Safety gear: eye protection, hearing protection, dust mask

Wood options that make sense for a kitchen table

The best wood is the one you can get straight, dry, and within budget. Pine is affordable and easy to

work with (and dents if you glare at it too hard). Poplar paints beautifully. Oak and maple are tough

and classic, but cost more and can be heavier to mill and finish.

Pro tip: let your boards acclimate indoors for about a week before building. Wood is

dramatic about humidity changes, and it will move.

A Simple, Sturdy Build Plan: 6-Foot Rectangular Kitchen Table

Below is a reliable beginner plan: a 72″ × 36″ top, about 30″ tall. You can scale the length up or down

without changing the basic structure.

Materials list (example build)

- Top: Five 1″ × 8″ boards (or similar) cut to 72″ (actual thickness is typically 3/4″)

- Legs: Four 4″ × 4″ posts cut to table height minus top thickness (or laminated legs)

- Aprons: 1″ × 4″ or 2″ × 4″ boards for the frame under the top

- Bracing: Corner blocks/braces + optional center stretcher

- Fasteners: Screws + tabletop fasteners (figure-8s or Z-clips) or slotted holes

- Finish: Stain/paint (optional) + protective clear coat (polyurethane/polyacrylic)

Cut list (adjust as needed)

This is a simple cut list conceptuallyexact apron lengths depend on your leg thickness and whether you

want the apron inset.

- Legs (4): ~29 1/4″ (assuming 3/4″ top and aiming near 30″ finished height)

- Long aprons (2): ~65″ (72″ top minus leg thickness and small inset)

- Short aprons (2): ~29″–31″ (depends on design and leg layout)

- Optional center stretcher (1): same length as long apron span

- Top boards (5): 72″

- Corner braces/blocks (4): small triangles or 45° blocks

If you want a truly foolproof workflow: sketch your base as a rectangle and “measure the openings”

between legs for apron lengths. Real-world building beats guessing, every time.

Step-by-Step: Build Your Kitchen Table

Step 1: Prep the wood (the boring step that makes everything easier)

Sand rough boards lightly to remove splinters and mill marks. Check edges for straightness. If boards

are slightly bowed, orient crowns in alternating directions so the final top behaves better.

Step 2: Build the base frame (legs + aprons)

The base is what prevents “table wobble”the enemy of coffee cups and your patience. Attach the long

and short aprons to the legs, keeping the frame square. Pocket holes are a popular beginner method

because they pull joints tight and hide screws on the inside faces.

- Dry-fit everything first (no glue) to confirm lengths and alignment.

- Use clamps to hold aprons flush while you fasten.

- Measure corner-to-corner diagonals; equal diagonals = square frame.

Step 3: Add corner bracing and a stretcher (sturdiness upgrade)

Corner braces (blocks or 45° braces) stiffen the base and reduce racking (side-to-side sway). A center

stretcher helps support a long tabletop and keeps the base from twisting over time.

Translation: your table won’t feel like it’s auditioning to be a trampoline.

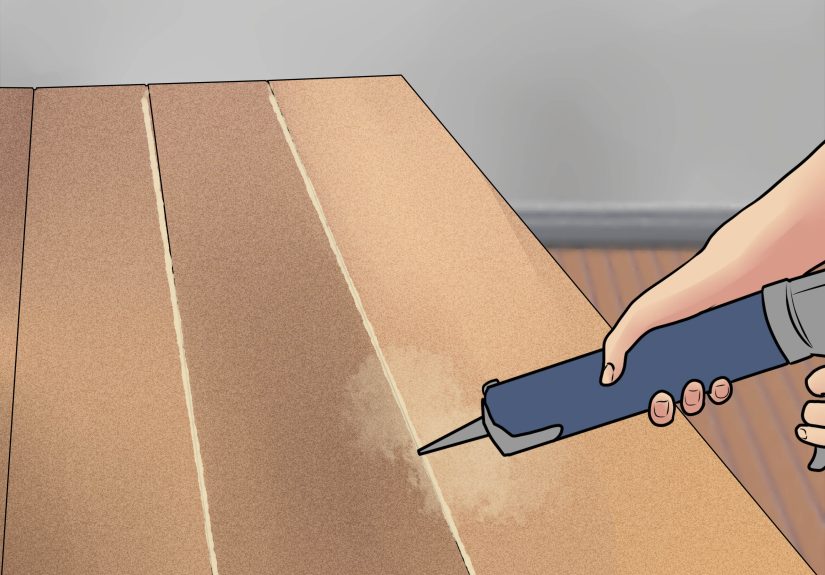

Step 4: Build the tabletop (the “big glue-up” moment)

Arrange your top boards on the floor or a work surface with the best faces down, then decide grain and

color order. If you’re gluing edges, apply glue evenly, clamp the boards, and wipe squeeze-out with a

damp rag before it turns into a crunchy ridge.

Some builders also use pocket screws underneath to help alignment. If you do, keep screw spacing

consistent and don’t over-tightenwood fibers can strip, and then you’ll invent new words.

Step 5: Flatten, sand, and soften edges

Once the top is assembled, sand it gradually (80 → 120 → 180 → 220). Break the sharp edges with a light

sanding pass or a small round-over. Sharp corners don’t just look harshthey chip, dent, and snag sleeves.

Step 6: Attach the top the right way (wood movement matters)

Here’s the rule that saves tabletops: wood expands and contracts across the grain.

A wide tabletop needs a mounting method that lets it move seasonally. If you screw it down rigidly, the

top can crack, warp, or split.

Good attachment options:

- Figure-8 fasteners: pivot as the top moves.

- Z-clips: slide in a kerf/slot along the apron.

- Slotted holes or stretchers: allow screws to travel slightly as the top shifts.

- Wood buttons: traditional and effective if you like an all-wood solution.

Center your base on the underside of the top, then attach using your chosen method. Don’t force the wood

to “behave.” It won’t. It’s wood.

Step 7: Finish for real kitchen life (heat, spills, and chaos)

Kitchens are hard on furniture. Use a protective topcoat like polyurethane or polyacrylic, and apply

multiple thin coats with light sanding between coats. If you’re staining softwood (like pine), consider

a pre-stain conditioner for a more even look.

Let the finish cure fully before heavy use. “Dry to the touch” is not the same thing as “ready for a hot

pizza box and a science fair volcano.”

Step 8: Stop wobble before it starts

Floors aren’t perfectly flatespecially in older homes. Add felt pads or adjustable leveling feet if

needed. If the wobble is in the base, re-check for square and tighten joints. A tiny twist in assembly

becomes a big wobble in daily use.

Common Mistakes (So You Don’t Have to Learn Them the Hard Way)

- Skipping wood acclimation: boards move after you build, not beforecongrats, you built a potato chip.

- Ignoring wood movement: rigidly screwing down a wide top invites cracks and splits.

- Not checking for square: if the base isn’t square, nothing fits nicely and everything looks “off.”

- Over-sanding edges late: soften edges early; it’s easier and looks intentional.

- Rushing finish: the fastest path to a sticky tabletop is “one thick coat should do it.”

Easy Upgrades That Make Your Table Look Custom

Add a breadboard end (with the right joinery)

Breadboard ends can help with alignment and give a classic look, but they must allow wood movement.

If you want this feature, research the correct approach before committingthis is an “upgrade,” not a

“wing it and hope” moment.

Use premade legs for a cleaner build

Buying table legs (tapered, turned, metal, or hairpin) lets you focus your effort on a beautiful top.

It’s not cheating; it’s design strategy. Your kitchen doesn’t care how heroic your joinery wasyour

kitchen cares that the table is solid.

Build a matching bench

Benches are often simpler than chairs and can make a smaller space feel more open. If your table is

farmhouse style, a bench is basically the sidekick that completes the outfit.

Real-World Experiences: What Building a Kitchen Table Actually Feels Like ()

Here’s the part most tutorials skip: the “human experience” of building a kitchen table. On paper, it’s

a list of steps. In real life, it’s a small adventure starring you, a pile of boards, and at least one

moment where you stare into the middle distance thinking, “Why is wood like this?”

The first experience usually happens at the lumber rack. You walk in confident. You walk out wiser.

Picking straight boards is like speed dating: you’re scanning for red flags (twist, bow, checks, ugly

knots in the wrong spots) while pretending you totally know what you’re doing. You’ll learn quickly

that the best boards are rarely stacked at eye level, and you’ll develop a respectful relationship with

the phrase “check for straightness down the length.”

Next comes cutting and fittingwhere many first-timers discover that measuring is not the same thing as

measuring accurately. The good news is you can build forgiveness into the process: label parts, dry-fit

everything, and only commit with glue and screws when you’re sure. The first time you clamp the base

together and the diagonals match, it feels like winning a tiny championship.

Then there’s the tabletop glue-up, the emotional centerpiece of the project. You’ll set up clamps, apply

glue, and suddenly feel like you need eight hands. Glue squeeze-out will appear everywhereon the seam,

on your fingers, on a clamp handle, and somehow on your elbow. Wiping it early is a magical move; waiting

until it dries is a lesson in regret, because dried glue laughs at stain.

Sanding is where patience gets tested. The first pass feels productive. The second pass feels reasonable.

By the third grit change, you start bargaining with yourself (“This is smooth enough… right?”). But when

you finally run your hand across a tabletop that feels consistently smooth, it’s worth it. A kitchen

table is tactile furniturepeople touch it constantlyso smoothness is not optional.

Finishing is the quiet drama. Dust appears out of nowhere. A single dog hair can teleport into wet

polyurethane like it has a mission. You learn to vacuum, tack-cloth, and work in calmer conditions.

Multiple thin coats feel slow, but the final result looks better and holds up to real life: hot mugs,

spills, and the occasional “oops” moment with a fork.

Finally, the “first week of ownership” teaches you what matters most. You’ll notice whether chairs tuck

in easily, whether knees hit the apron, and whether the table feels solid when someone leans on it. If

you attached the top in a way that allows movement, you’ll sleep better when seasons change. And if you

built it square and braced it well, your table won’t develop that subtle wiggle that drives everyone

quietly insane. The best part? Every time you sit down to eat, you’ll know exactly how it’s builtbecause

you built it.

Final Thoughts

Building a kitchen table is one of the best “big payoff” woodworking projects: the structure is

straightforward, the result is used every day, and the skills carry into future builds. Plan your size,

build a square base, make a strong top, and attach it in a way that respects wood movement. Do that, and

you won’t just have a tableyou’ll have the kind of table that becomes part of the home’s story.